Select the Correct Filter Cartridge

EP Editorial Staff | October 4, 2022

No matter the application, there is an effective filter medium if you understand the options.

By Alexander Bachmann, Eaton Technologies GmbH

The finer, the better? Filtration is not quite that simple. The filter cartridge with the highest retention rate does not automatically guarantee the best filtration result. Several factors need to be considered to ensure optimal performance. With the right background knowledge, users can quickly narrow down the selection, ensuring that processes run economically and efficiently.

Whether in wastewater treatment, chemical production, or microchip factories, filtration is now a fundamental process in most industries. This is because separating solids and liquids is essential for removing unwanted particles from end or intermediate products. If the aim is to ensure a certain degree of purity, filter cartridges are used as police filters in the final filtration step.

Filtration properties for every application

Different versions of filter cartridges are available to meet needs in industrial, chemical, microelectronic, and oil and gas market segments. This means that even critical requirements that call for a high and consistent filter-medium retention efficiency can be met. When choosing the right filter cartridge, users need to consider various factors to achieve the optimal level of performance.

Some of the most important criteria include:

• Filter operating principles

• Process conditions, such as flow rate, pressure, temperature, and dynamic viscosity

• Filter material retention rate and size of particles to be removed

• Design principles and components.

From a technical point of view, filter cartridges are differentiated according to two principles: surface and depth filtration. With surface filtration, particles and solids are retained on the surface; depth filtration retains particles within the filter medium.

Dynamic interaction

Retention rates of filter cartridges can range from 250 to 0.03 µm. These process conditions can have a significant impact on the performance of cartridges:

• Operating pressure determines the thickness of the filter housing shell

• Operating temperature determines the housing material (stainless steel or plastic)

• Volume flow determines housing size

• Dynamic viscosity has a direct effect on the differential pressure and, therefore, the size of the housing

• Chemical compatibility has a direct effect on the choice of housing material.

The shape, concentration and composition of the particles also play an important role when selecting a suitable filter medium. Chemical and thermal compatibility also must not be overlooked.

All eyes on retention rate

Retention rate, either absolute or nominal, has a direct effect on the filtration result. Filtration may require that only specific contaminants to be removed, while contaminants that are not critical to the process or that are valuable may or must remain in the filtrate.

The beta ratio provides information about the retention efficiency and thus the performance of the filter cartridge.

If all particles of a specified size need to be removed, a filter cartridge with an absolute retention rate is required. The absolute retention rate indicates the pore size of the filter medium. All particles that do not fit through the pores are reliably retained according to a retention efficiency defined under laboratory conditions. For example, an absolute retention rate of 10 μm means that particles at least 10 μm in size are retained with one pass through the filter cartridge. If 5,000 of these particles are measured in the liquid before filtration and only one particle is measured in the filtrate after filtration, the filter cartridge has achieved a beta ratio of 5000. This corresponds to a retention efficiency of 99.98%.

A nominal retention rate, on the other hand, refers to a filter cartridge that retains an undefined percentage of solid particles that are larger than the specified pore size.

Filter cartridges can be uniformly assessed according to their retention rate. The general operating principle is also always the same: A fluid flows through the filter cartridge from the outside inward, separating the particles. However, there are differences in the technology and design.

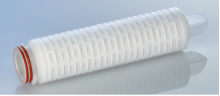

The size of the filter cartridge determines the size of the filter surface. To maximize the surface, the filter material can be pleated by folding the filter media sheets like a harmonica. The exception to this is melt-blown depth filter cartridges.

To provide the right filter cartridge for every application, cartridges are available in different diameters and lengths. For example, the outer diameter of the typical and frequently used size is between 60 and 72 mm (2.4 and 2.8 in.). Standard lengths vary from 127 to 1,778 mm (5 to 70 in.). Adapters allow cartridges to be installed in different housing types. Common adapter designs are the Double Open End (DOE) version, open on both sides, and Single Open End (SOE) version, open on one side. The flow direction of filter cartridges is usually from the outside inward.

The most common cartridge types include:

• String-wound filter cartridges, which are depth-filter media made of staple fibers, suitable for separating contaminants with a wide range of particle sizes (clarification). These cartridges also boast a high dirt-holding capacity and a long service life. Originally made from cotton, there are now alternatives made from polypropylene, fiberglass, polyamide, polyester, and polyphenylene sulfide. The inner cores are usually made from polypropylene or stainless steel. They are typically used to filter process chemicals, solvents, galvanic baths, acids, alkalis, process water, and to desalinate sea water.

• Activated carbon cartridges are available in two basic designs. One uses granular activated carbon in a porous polyethylene cage with polypropylene end caps and a particulate pre-filter. The other design uses sintered activated-carbon blocks with a particulate pre-filter made from a polypropylene net or fleece and corresponding end caps. Activated carbon filter cartridges are used to filer process water, water-based and organic solutions, and to remove organic contaminants from galvanic nickel or copper baths.

• Melt-blown depth filter cartridges are made from pure polymers, meaning they are suitable for separating contaminants with a wide range of particle sizes, as well as removing all particles of a specified pore size (classification). They are available with nominal retention efficiencies of 80% to 95% and with an absolute retention efficiency of 99.98%. Standard filter materials include polypropylene, polyamide, and polyester. They can be used to filter ultra-pure water, acids, alkalis, emulsions, e-coatings (electro-coating in automotive), solvents, amines, glycols, hydrocarbons (kerosene), water- and solvent-based paints, lacquers, emulsions, waxes, and condensates.

• Pleated filter cartridges have a large filter surface of approx. 0.5 to 0.7 m² per 254-mm (10 in.) element, which enables high flow rates with low initial differential pressure. Filter materials include polypropylene, fiberglass, polyamide, and polyester.

High flow filter cartridges also belong to this group and can be used to handle particularly high flow volumes. However, they differ not only in terms of their outer diameter, which is approximately 152 or 165 mm (6 or 6.5″), but also in terms of their flow direction, which unlike most other filter cartridges is from the inside outward.

Pleated filter cartridges are used to filter process water, wastewater, chemicals and inks, part-cleaning solutions, and for pre-filtration in reverse-osmosis water systems.

• Membrane filter cartridges use a pleated surface that ranges from approx. 0.5 to 0.9 m² per 254-mm (10 in.) element. Available filter materials include polyethersulfone, polysulfone, polyamide 6.6, and polytetrafluoroethylene, among others. Applications are usually linked to required absolute retention rates.

• Metal filter cartridges typically use stainless steel in a cylindrical or pleated wire-mesh structure. They are also available in a sintered design, commonly with titanium filter material. They are especially suitable for high-temperature applications (698 F/370 C) and to filter corrosive liquids and gases, cryogenic fluids, high-viscosity solutions, process steam, and for catalyst recovery.

Determining which filter cartridge is suitable for which application depends on process parameters, the required performance, and economic factors. For operators who need efficient filtration, it is therefore worth taking a closer look at the available options.

Alexander Bachmann is Senior Application Engineer, Eaton Technologies GmbH, Germany. Click here to learn more about filtration technology and filter options.

View Comments