Featured Posts

-

PODCAST: Use A Service For Your Condition Monitoring

PODCAST: Use A Service For Your Condition MonitoringIt’s well established that an effective condition-monitoring program can significantly raise your asset reliability and efficiency to world-class levels. The result will be greatly reduced maintenance costs, extended asset life, and improved production and product quality. But, implementing a condition-monitoring program internally can be a daunting task. An option that may better fit your operation […]

-

Vibration Monitor Delivers Reliable Data

Vibration Monitor Delivers Reliable DataThe AMS Wireless Vibration Monitor uses PeakVue Plus technology to provide a reliable indication of asset health. By Drew Mackley, Emerson Today’s leaner maintenance and reliability teams can no longer rely solely on scheduled data-collection routes. Today’s most efficient plants need their people focused on driving increased reliability, sustainability, and performance, not walking around collecting […]

-

Built-In Condition Monitoring Increases Efficiency

Built-In Condition Monitoring Increases EfficiencyModern smart instruments monitor and transmit large volumes of process and diagnostic data to reduce maintenance efforts and increase uptime. By Keith Riley, Endress+Hauser Modern plants use vast installations of instrumentation to continuously monitor and control their processes, with the goal of maximizing operational productivity, product quality, and process/personnel safety. Instrumentation ranges from inline process […]

ON THE FLOOR

Each month we talk with maintenance and technology professionals about their views and pressing problems on the factory floor.

-

The Future of Maintenance

The Future of MaintenanceBy Dr. Klaus M. Blache, Univ. of Tennessee Reliability and Maintainability Center (RMC)

Featured Posts

-

PODCAST: Use A Service For Your Condition Monitoring

PODCAST: Use A Service For Your Condition MonitoringIt’s well established that an effective condition-monitoring program can significantly raise your asset reliability and efficiency to world-class levels. The result will be greatly reduced maintenance costs, extended asset life, and improved production and product quality. But, implementing a condition-monitoring program internally can be a daunting task. An option that may better fit your operation […]

-

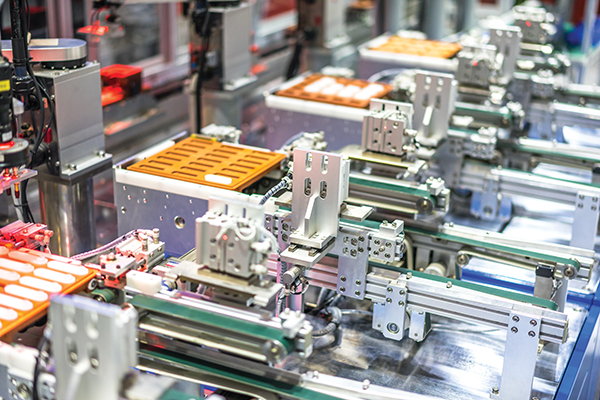

Properly Place Your Sensors

Properly Place Your SensorsA well thought out sensor-placement strategy will pay off with better data and increased reliability. By Eric Whitley, L2L Within the complex field of Industry 4.0, the role of sensors in industrial operations cannot be overstated. These tiny devices act as the eyes and ears of a manufacturing unit, gathering crucial data that can make […]

Featured Posts

-

Do You Have Practical Intelligence?

Do You Have Practical Intelligence?By Dr. Klaus M. Blache, Univ. of Tennessee Reliability and Maintainability Center (RMC) I’ve often stated in training that the person in the room who can listen to all of the smart people discussing an initiative, trying to solve a problem, or deciding on a direction, and take that collective input and sketch out/elaborate on […]

-

AI: Good or Bad?

AI: Good or Bad?Artificial intelligence (AI) is everywhere you look—internet, financial, transportation, agriculture, research, fashion, health care, writing, and manufacturing. When I was writing a recent LinkedIn post, the first prompt was, “Let AI help you with the first draft.” (I turned it down). Some are excited to be able to interact with AI and others are fearful […]

-

Use Best Practices For MRO Inventory

Use Best Practices For MRO InventoryMy review of data from more than 200 facilities indicates MRO (maintenance, repair, and operations) inventory reductions of 10% to 50% are possible. MRO includes all the consumable materials and supplies needed to support operations (machinery, equipment, tools) with items such as spare parts, cleaning supplies, and gloves. The two most efficient ways to attain […]

Featured Posts

-

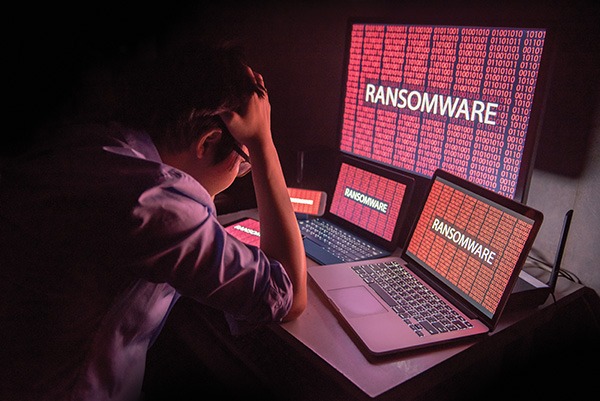

Enterprise MES Connects Your Plants

Enterprise MES Connects Your PlantsAdopting digital technologies across distributed manufacturing systems drives powerful efficiency and flexibility gains. By Keith Chambers, AVEVA Global manufacturers are battling supply chain headwinds and rampant competition, all the while striving to slash expenses and adopt more sustainable operating practices. Amid this pressurized backdrop, organizations are addressing the challenge by running multiple plant facilities in […]

-

R&M Challenges And Opportunities

R&M Challenges And OpportunitiesAs we look to the near future, reliability and maintenance professionals face numerous challenges and opportunities in their continuing quest to support mission-critical goals and improve operational performance: Challenge: Skilled maintenance technicians/trades are difficult to find/hire/retain, while experienced people are retiring. Opportunity: Millennials are getting somewhat more interested in reliability and maintenance because of newer […]

Featured Posts

-

Properly Place Your Sensors

Properly Place Your SensorsA well thought out sensor-placement strategy will pay off with better data and increased reliability. By Eric Whitley, L2L Within the complex field of Industry 4.0, the role of sensors in industrial operations cannot be overstated. These tiny devices act as the eyes and ears of a manufacturing unit, gathering crucial data that can make […]

-

Take Manual Out Of Maintenance

Take Manual Out Of MaintenanceSmart instrumentation, with diagnostics and verification capabilities, advances uptime and safety in process systems. By Bethany Silva, Endress+Hauser In the process industries, maintenance is necessary to preserve equipment health, maintain operational safety, and ensure product quality. Until recently, most maintenance was performed manually because there were limited options. This type of work takes considerable time […]

-

Innovation Meets Future Conveyor Needs

Innovation Meets Future Conveyor NeedsMonitoring and automation advances make it possible to increase conveyor speeds without sacrificing safety or efficiency. By R. Todd Swinderman, Martin Engineering Higher production demands across all bulk-handling segments require increased efficiency at the lowest cost of operation, in the safest and most effective manner possible. As conveyor systems become wider, faster, and longer, more […]

Featured Posts

-

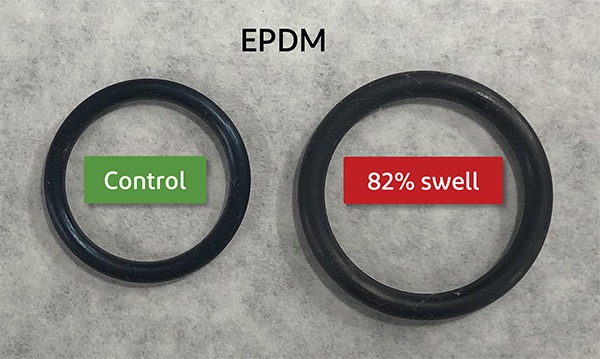

Evaluate Before Lubricating Polymers

Evaluate Before Lubricating PolymersIncompatibility between polymers and lubricants can cause physical changes that affect functional properties. By William Fick, DuPont While lubricants are typically used to minimize wear between metal parts, they also need to lubricate polymer or elastomer parts without damaging them. Understanding how materials interact with each other and identifying compatible combinations can be a challenging […]

-

Champion Good Lube Practices

Champion Good Lube PracticesThe power of one person, dedicated to a quality program, can result in long-term gains in asset reliability. By Dave Piangerelli, Lubrication Technologies Inc. When on site at a plant, a quarry, a municipality, or any company/entity that uses lubricants, it’s easy to spot inefficiency and poor management and, alternately, good management practices. The most […]

-

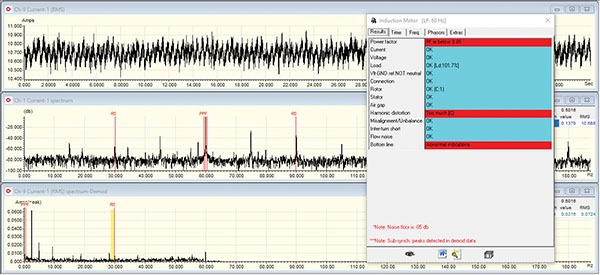

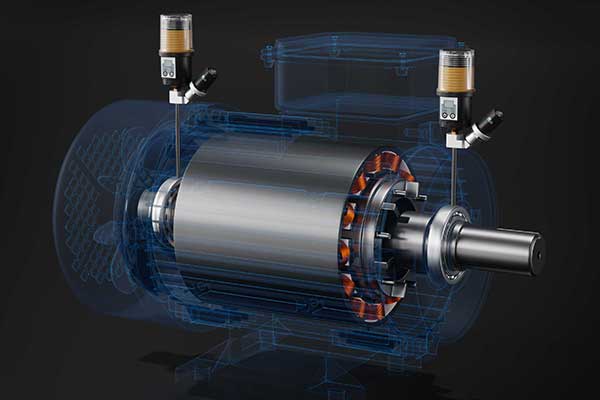

Featured Product: Keep An Extra EYE On Your Motors

Featured Product: Keep An Extra EYE On Your MotorsIn today’s competitive marketplace, motor reliability is essential. However, monitoring motor health is increasingly difficult in today’s shrinking labor force environment. Companies seeking to gain a competitive edge are turning to permanently installed motor testing technology which improves motor reliability, is safer than manual testing, addresses the reduced labor force issue, and provides a […]

-

Wireless Bearing Maintenance

Wireless Bearing MaintenanceUE Systems, Elmsford, NY (uesystems.com), a developer of ultrasonic detection instruments and solutions for maintenance and reliability, has introduced the OnTrak Wireless system. This solution actively prevents failures through precision autonomous lubrication, which addresses lubrication-related issues that account for a significant portion of premature bearing failures. According to Blair Fraser, Vice President of Business […]

-

M12 Ready Signaling Solutions

M12 Ready Signaling SolutionsM12 connectable audible, visual, combination, and stacklights save time & money on installation. Pfannenberg, Inc., Lancaser, NY (pfannenbergusa.com), a global manufacturer of thermal management and signaling technologies, announces that their full product range of audible, visual, combination, and stacklights is now available with M12 readiness. M12 technology removes the need for an electrician or electrical […]

-

Crane Brakes Stop Downtime

Crane Brakes Stop DowntimeReplacing the brakes on two 40-ton cranes has virtually eliminated ongoing maintenance issues. If you can’t take the heat, stay out of the heat-exchange business. For Ryan Dorman, Facilities Manager at Ohmstede Ltd., Beaumont, TX (ohmstede.net), the key to beating the heat and keeping his cool was addressing the 40-ton elephant in the room—a 40-ton […]

-

Automation Architecture

Automation ArchitectureBoundless Automation is the foundation of the company’s next-generation, software-centric automation architecture said to create a more advanced automation platform that contextualizes and democratizes data for people and artificial intelligence engines. DeltaV edge environment provides more secure ways to move data from the automation platform to wherever it is needed including data lakes, data scientists, […]

-

Fume hood

Fume hoodTorit fume hood for robotic and manual welding applications is low-profile to allow a more flexible installation than traditional canopy-style hoods. When paired with the optional weld curtains, it can be sized to reduce airflow requirements, ultimately lowering the overall cost of a dust-collection system. Available in multiple sizes in free-standing and ceiling-mounted configurations, it […]

-

Flexible split conduit

Flexible split conduitMurrplastik EWT-PA series flexible, non-metallic, two-piece split conduit reportedly provides a solution for routing pre-terminated cables, eliminating the need to dismantle/reassemble the installed connectors. The conduit consists of dual overlapping tubes said to be easy to open yet provide mechanical protection and eliminate unintentional exposure of the cabling bundle inside. Connectors and accessories to aid […]

POPULAR CATEGORIES