Measure Motor Temperatures Correctly

EP Editorial Staff | November 15, 2017

By Jim Seffrin, Director, Infraspection Institute

In 1997, a research project led by Infraspection Institute (infraspection.com, Burlington, NJ) used instrumented motors in a controlled environment to determine the effect of excess force on installed units. One of our primary goals was to identify a location for collecting reliable temperature data.

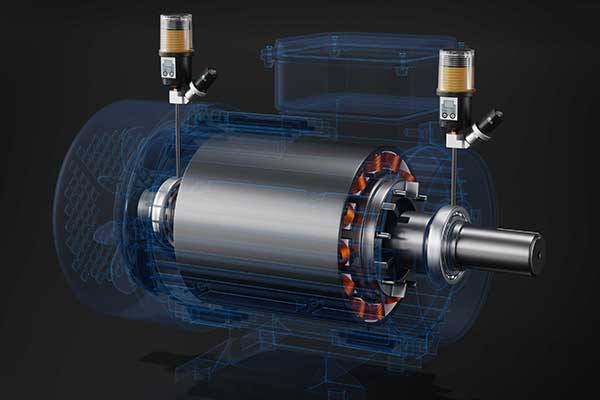

The research found that measuring on the exterior of the motor bell-housing within 1 in. of the output driveshaft consistently produced temperatures that were within 1 C to 2 C of the motor windings and the output side bearing assembly. Temperatures taken at the bell-housing were especially useful for fan-cooled motors since this area was unaffected by convective cooling from the fan.

When measuring motor temperatures, keep the following in mind:

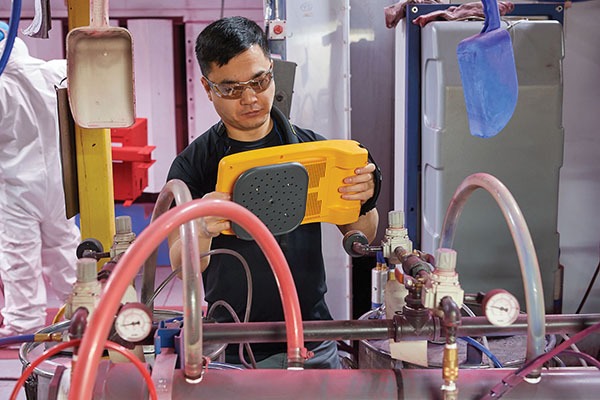

• Make certain that all thermometers are within calibration and used properly.

• Motor temperature will vary with load and ambient temperature. Be sure to record both along with the motor temperature.

• Elevated temperatures can be caused by electrical or mechanical defects within the motor and/or defective installations.

• Motors with elevated temperatures should be further investigated and repaired or replaced.

Determining a Motor’s Maximum Operating Temperature

Exceeding the maximum operating temperature of a motor will shorten the life of its dielectric materials and decrease the unit’s service life. Determining that crucial temperature requires one to know the motor’s ambient temperature rating and its rated temperature rise above ambient. Both of these values are generally found on the nameplate located on the exterior of the motor casing.

To calculate maximum operating temperature, add the ambient and rated rise temperatures. Their sum is the maximum operating temperature for the subject motor at 100% load.

Example:

Rated Ambient: 40 C

Rated Rise: 90 C

40 + 90 = 130 C or 266 F

It’s important to note that some motors specify insulation class rather than a numeric value for temperature rise. In such cases, it is necessary to know the operating limits for the insulation class of the subject motor. EP

Jim Seffrin, a practicing thermographer with more than 30 years of experience in the field, was appointed to the position of Director of Infraspection Institute in 2000. This article is based on several of his “Tip of the Week” posts on IRINFO.org. For information on various workplace topics and infrared-related issues, and various upcoming training and certification opportunities, email [email protected] or visit infraspection.com.

View Comments