Integrating Robots Into Your Workforce

Klaus M. Blache | March 1, 2022

I’m getting ready to participate in several job interviews to select the best candidate.

The job requires being able to perform in a fast-paced manufacturing environment. Other skills and requirements include being aware of and able to adjust to surrounding events, knowing what acceptable quality is, reliable attendance, ability to work well under stress, willing to work any shift and long hours as necessary, won’t ask for a raise every year, and yes, it will be a robot.

The IFR (International Federation of Robotics, Frankfurt, Germany, ifr.org) stated that, in 2021, almost 13% of the automotive workforce was robots. IFR also indicates that, in the next decade, many of the new hires will be cobots (collaborative robots). They will assist maintenance workers with heavy lifting and holding/reaching/passing tools and parts. Robots are better at heavy lifting, repetitive tasks, rate of work, and standardized work is always followed.

At the same time, more than two-million baby boomers will retire with their inherent knowledge of keeping a plant running. This will make integration of Industry 4.0/IIoT and AI/Machine Learning more difficult.

The introduction of new technology changes an enterprise’s social system. Also, much depends on organizational complexity, including reporting structure, clarity of processes, level of standardized work, and number of tasks. Greater complexity makes communication more difficult. The people who are concerned about the number of robots at work need to understand and accept that the number will increase, but they won’t replace all jobs.

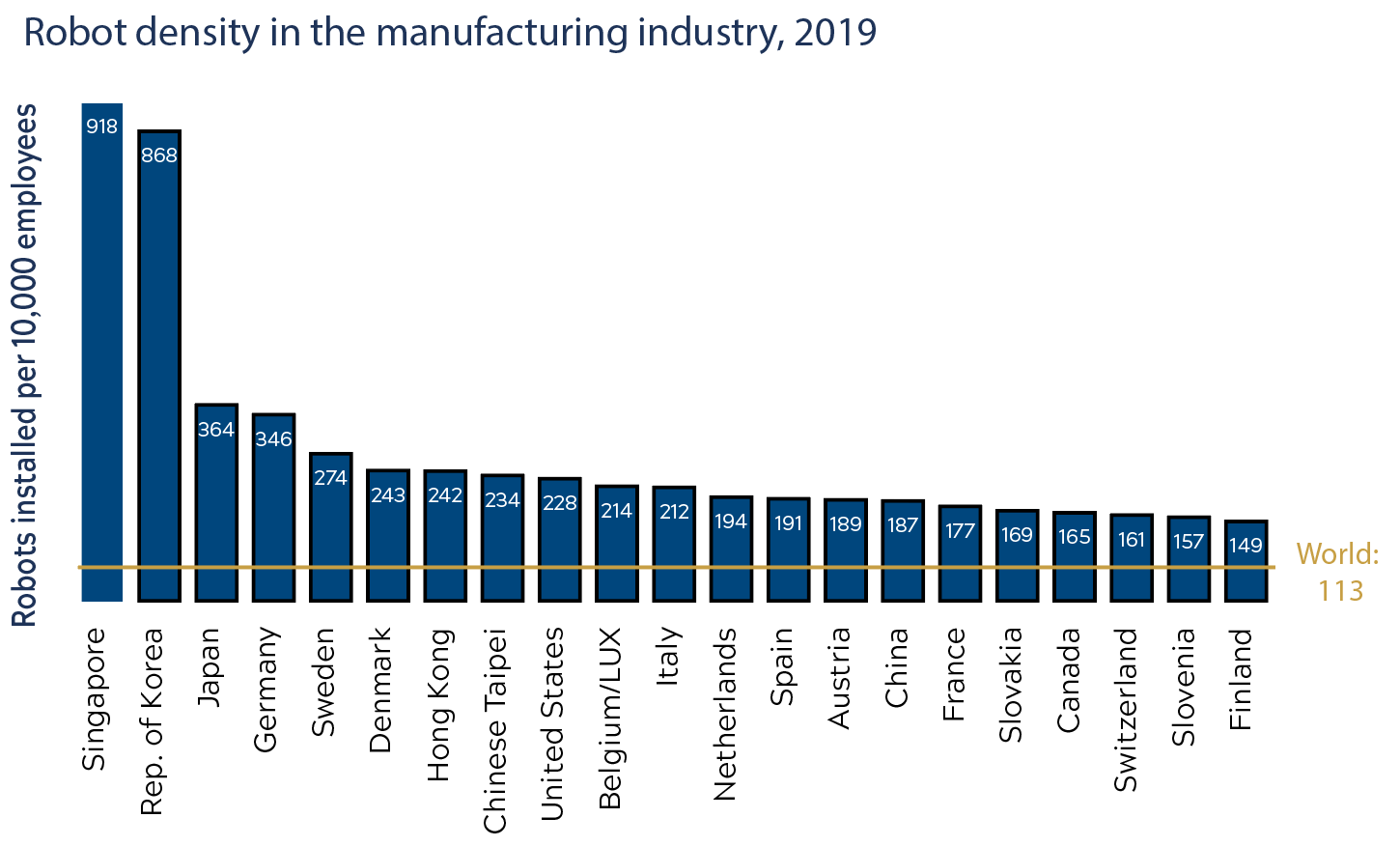

“In the U.S., four manufacturing industries account for 70% of robots: automakers, 38% of robots in use; electronics, 15%; the plastics and chemical industry, 10%; and metals manufacturers, 7%. Though the U.S. is a technologically very advanced economy, in terms of industrial robot production, use, and innovation, it’s behind many other advanced economies.” (“How many jobs do robots really replace?,” MIT News, Massachusetts Institute of Technology, Cambridge.)

In 2021, 12.9% of the automotive workforce was robots. However, for all of the United States, that number is only 2.3%. This places the U.S. 9th in the robot density ranking of global economies. Singapore holds the top position at 9.2%.

Robots, compared with humans, are better at lifting heavy objects; faster; work with more precision; are better at sensing sound, movement, and air quality; make fewer mistakes than humans; and do not fatigue. Humans are still better at making decisions, innovating, and showing feelings (empathy). Human interaction is still a big part of operational success and that won’t change quickly. We can all think of a recent automated response on a phone call (run by algorithms) that frustrated us because we wanted to talk with a real person. In contrast, the second annual AI at Work study conducted by Oracle (oracle.com) and Future Workplace (futureworkplace.com) performed a study of 8,370 employees, managers, and HR leaders in ten countries. They found that 64% of people would trust a robot more than their managers. Also, half have turned to a robot for advice (instead of their manager).

A study by the Technical Univ. of Munich (TUM) and Erasmus Univ. in Rotterdam showed that people in general feel better when being replaced by other human workers. However, when it’s their own job loss they would rather be replaced by robots than by another person. It’s about psychological impact and maintaining self-esteem.

In the future factory, human personnel will do less repetitive motion, lifting, and other physical tasks. Properly integrating the human (communication and higher-level thinking tasks) in the loop will enhance AI/machine learning applications and overall Industry 4.0 results. EP

Based in Knoxville, Dr. Klaus M. Blache is director of the Reliability & Maintainability Center at the Univ. of Tennessee, and a research professor in the College of Engineering. Contact him at kblache@utk.edu.

View Comments