Electrical Assets Holding You Back?

EP Editorial Staff | October 1, 2022

Level up your electrical infrastructure to create a budget-friendly foundation for a connected plant.

An electrical outage at your chemical plant takes several process units offline. Your operations team scrambles to figure out why and soon pulls in maintenance teams. As time passes, logistics begins scurrying to manage the growing logjam of raw materials as tanks fill up and product shipments get delayed. As everyone’s stress level rises, operating costs add up and margins shrink. Finally, many hours and hundreds of thousands of dollars in losses later, the issue is resolved.

No one knows what exactly caused the trip. But you know the same threat will hang over the plant every day until you can access real-time data and identify the culprit.

You can avoid this situation in the future by implementing a digital solution, but how do you do that with a limited capital expenditure budget? And if you could, where would you even start?

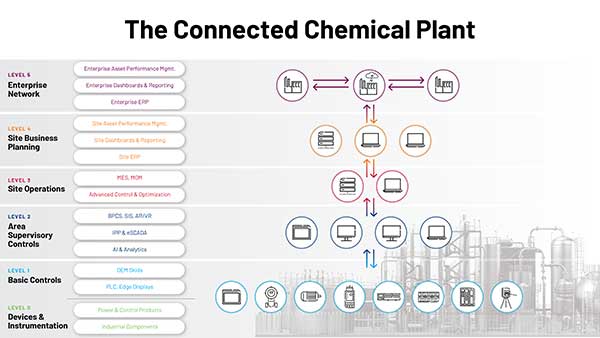

Here’s an idea: Lay the foundation for a connected plant by starting at zero. That is Level 0, your electrical devices and instrumentation (Fig. 1 below).

Fig. 1: Five levels to a connected plant. Figure 1 outlines a five-level approach for achieving a connected, digitally transformed processing/manufacturing plant. Courtesy Rockwell Automation

This approach allows you to do small projects one at a time, using operating expenses. It also creates a scalable solution that is appropriate for your budget and schedule. Even better? The first step will pay for itself after your first shut down. So too will the next steps as you’re able to speed decision making by determining first out, increasing uptime, maximizing asset utilization, mitigating potential risks, and increasing OEE. Furthermore, digital transformation at the lowest levels paves the way for continuing the connection to the enterprise level, giving management the ability to make critical business decisions regarding plant-to-plant or site-to-site capacity and performance.

Following is guidance on useful places to start. It is helpful to enlist an objective evaluation of your current automation infrastructure to pinpoint opportunities that offer high value with low effort, along with those on a continuum that can eventually transform your entire facility.

Connect devices

Before you can get access to data analytics, you need your Level 0 industrial devices on the production floor to be able to communicate digitally. Then you must connect them with the Level 1 power and control devices. Focus on deploying intelligent motor controls, variable-speed drives, low-voltage breakers, and protection relays that are compatible with EtherNet/IP or IEC 61850. This will enable you to capture the data from the devices to inform basic operations and maintenance needs.

For example, digitalization of the protection relays in your power distribution enables simple time stamping. In the scenario described above, this simple connection would have helped determine what tripped first and whether the outage originated at the utility service or inside the plant. Then, the team could have isolated the issue, resolved the failure, and gotten the plant back up and running sooner.

Making these data connections can be done easily in a matter of days or by simply specifying devices compatible with EtherNet/IP or IEC 61850 as you replace aging field equipment. Put in the Ethernet switch and connect it to the controller—voila! This can be done in one step or two, meaning upgrade the equipment and connect it later using the EtherNet/IP or IEC 61850 open communications standards, or do both at once. To make it even easier, you can order kits to have at the ready as you replace end-of-life devices with new ones. As you increase the number of smart devices in your electrical system, you’ll become more informed.

Your plant might be farther along than you think. In one case, an evaluation of current equipment at a large petrochemical plant in Texas revealed that 75% of its installed devices were smart. They just needed to be networked together to get the data flowing and the digital transformation kickstarted.

Once information is moving from intelligent electrical devices to the control system, you can make the data accessible from any operator control station.

Assess your control system

Integrated power-control systems can capture electrical data from aging production assets so you can monitor performance and help minimize unexpected downtime. You can use this data to better understand electrical distribution and motor-driven asset performance. It also can be used to schedule repairs or maintenance, instead of “white-knuckling” the risk of failure and being forced to react—or overcorrecting by performing unnecessary and costly maintenance. This data can also help you better monitor and optimize asset energy usage.

To make these types of upgrades easier, tap into packaged offerings—with all the elements of the electrical-distribution system—that provide plant personnel with total access to all the information in the substation. With these kinds of packages, all the devices can be digitally integrated, regardless of which manufacturer supplied the device.

Standardizing and consolidating technologies reduces the number of systems your team must support. This lowers operating expenses by providing for the use of common spare parts and reducing overhead and overtime for training.

Use the data

Finally, connect Level 1 to Level 2 to focus on making the data easy to access and use through human-machine-interface (HMI) displays. This makes it easier for your team to monitor what’s happening and when. In real-time, before a process alarm sounds, your personnel can be alerted to a potential electrical issue and begin the repair process, averting an unplanned event that will affect productivity and equipment performance.

You also can define and track trends to gain even more operational insights. For example, set a trend to track the transformer winding temperature. Then, if the temperature spikes unnaturally, the operator will be aware and can proactively address the potential failure. One refinery, for example, tapped into unified data to cut downtime related to equipment failures by 27%. They reduced costs related to maintenance troubleshooting

by 35%.

Another benefit of switching to a digital solution is the ability to support remote monitoring, which also helps improve the safety of your personnel and the health of your equipment. With an intelligent, integrated electrical system, personnel can even work from a smart phone or tablet, giving them distance from potentially hazardous conditions.

As your company takes step-by-step measures to digitally transform, more comprehensive and informative data can be captured, analyzed, and leveraged. For example, even at a rather basic device level, the technology stores information, providing an objective source of truth that your team can access and share, rather than relying on inconsistent manual shift notes. It also helps avoid blame games and finger pointing.

Consider the recent scenario in which a breaker in a large chemical plant kept tripping. After analyzing the stored performance data, the engineers determined the breaker performed its job and, in fact, the failure was due to personnel errors. Once revealed, they redirected the team and avoided buying an expensive piece of new equipment.

Building digital foundation

Whatever steps you take, you can make significant strides over time, and that are appropriate to your budgetary constraints, to implement a digital strategy in your plant. Even with the simplest digital capabilities in place, you can better monitor and upgrade aging electrical assets, as needed, and reduce the costs associated with supporting disparate systems and troubleshooting unplanned events.

From there, you can focus on creating opportunities to improve operations and processes, boost production, and gain understanding of energy use to reduce operating costs. Each step brings the organization closer to unlocking insights at all levels to manage risk and optimize performance. EP

Ramon Farach is Global Chemical Industry Technical Consultant for Rockwell Automation, Milwaukee (rockwellautomation.com). He provides industry and technical insights to help understand and solve customer challenges, develop product and service messaging, and support product development. Farach has more than 20 years of chemical industry experience in areas including process engineering, operations support, process design, installation and commissioning, and R&D.

View Comments